Blog

Talented performers often do that extra special something. Do you know what ...

By Christopher Allen, MA, PMI-ACP, Product Manager “There’s no better learning technique than preparing to teach others.” Valid? Yes. Implications? ...

Tools for Instructional Investigation: Finding the Root Cause of Waste and Failure

By Christopher Allen | September 20, 2017 | Custom Learning | 0 Comments

By Christopher Allen, MA, PMI-ACP, Product Manager

“There’s no better learning technique than preparing to teach others.”

Valid? Yes.

Implications?

This adage does presuppose that during preparation the instructor is working with the right information, uncovers the implied and important steps to getting it right, and masters the concepts well enough to build learning frameworks for their students. Without each of those components the effort is likely a big waste of everyone’s time.

Instructional Designers lean on Subject Matter Experts to outline and contribute substantial content in the form of scenarios, consequences, tips and best practices. But even with help, how do they know they have the right materials to help learners achieve superior performance? Or better yet, how do they discern the right materials out of the haystack of content they have been given.

Even though we may feel like we’re drowning in content and media, there are a number of ways to make sense of it all.

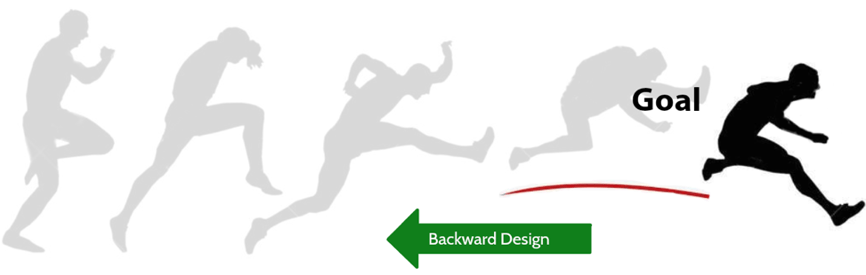

Work Backwards

One technique, preached over and over, is to work the course backwards. Start designing the last thing you would want students to demonstrate before heading off to perform. The penultimate scenario or set of scenarios is often the more expensive interactive component to build compared to the rest of the course. If the first thing you focus on is creating an authentic interaction that ‘puts it all together’, you’ve naturally included all the items that constitute the desired performance.

Should you run out of budget along the way, this technique should also prevent you from spending time and effort on peripheral concepts, while still producing a learning intervention that allows students to practice the entire desired performance.

Value Stream Mapping

Common goals for training interventions include: increasing quality, decreasing waste and achieving consistent performance. Value Stream Mapping is a valuable tool for identifying all the components of a process and analyzing where common mistakes occur and adjustments can be made to ensure desirable outcomes.

Value Stream Mapping is also a great group activity to help bring a team together. Assemble a small group of people who collectively perform all the functions of the area in question. The group should also be made up of both senior and staff level employees. Together they will diagram and define all the actions necessary to complete the process. Start by establishing boundaries on process to focus discussion on only the actions that happen with in a definable window. Example:

For example:

- Starting point: After customer service has identified that a replacement widget needs to be mailed to the client

- Ending point: Once the mailing label has been printed

As the map starts to come together, it will be important to add fidelity to each step description including:

- Time to complete the step

- Number of people involved in the step

- Sources of information needed to complete the step

- Machines or programs used

- Location of people, things and information

- Immediate and long-term risks

- Costs to complete perfectly or with complications

- Consequences of failure

A descriptive map of the process will be extraordinary valuable in supporting the development of learning events, as well as, determining what supporting materials need to be included to help learners adapt to different scenarios.

Ask Why FIVE Times

Showing the consequences of both best practices and poor performance, at any step along the way truly makes for compelling learning. (see the ‘F’ in CCAF).

To verify the true points of failure, one great technique to use is a form of Root Cause Analysis called 5Y. Take a known outcome of a poor performance and ask why did this happen several times, until clarity on the exact action or collection of actions can be identified. With each ‘Why’ asked, the goal is to drill down in granularity from symptoms of poor performance to the step or collection of steps where an action can be attributed to poor performance. Here’s an example of 5Y in action, from its inventor Taiichi Ohno:

- 1. Why did the machine stop? (There was an overload and the fuse blew.)

- 2. Why was there an overload? (The bearing was not sufficiently lubricated.)

- 3. Why was it not lubricated sufficiently? (The lubrication pump was not pumping sufficiently.)

- 4. Why was it not pumping sufficiently? (The shaft of the pump was worn and rattling.)

- 5. Why was the shaft worn out? (There was no strainer attached and metal scrap got in.)

Not only will 5Y help you identify the individual steps most likely to cause problems, you may also uncover steps or actions that can be removed to reduce waste or improved to lower risk.

Ask the IDs: What techniques do you use?

Many of our clients collaborate with us to design activities that solve a performance problem and help learners do the right thing. For example, whether it’s cooking the perfect hamburger, closing the sale at the right time, or creating a strong password to prevent cyber criminals from hacking your system, we design activities that allow learners to make mistakes behind the screen – not while they’re on the job – and learn from them. Our performance-based solutions truly help learners practice to mastery.

As we start our backgrounding work, one of our starter questions is usually around how the lesson or activity fits into the larger training plan. This question can help us see the big picture and often leads to a request to analyze current curriculum. We appreciate the opportunity to review existing training plans so we can map competencies to learning and performance objectives, leading to the discovery of content gaps. We can then decide the best way to address those gaps that will create the most effective learning solutions. Of course, if clients don’t have a training plan, we’re happy to develop one through analysis efforts.

I always start by crafting the Performance Objectives that describe the behavior you want learners to replicate following the learning experience. Ask questions like:

- What does it look like when someone is doing the task correctly?

- What are the verbs that describe the performance?

- What mistakes do new learners make when attempting the behavior?

- Why does following an established process matter?

- If two people were doing the same task, one correctly and one incorrectly, what is the difference in their performance?

Performance Objectives need to describe observable behavior. That means they will answer the question, “What does it look like?” Never use terms like “understand,” “comprehend,” “be aware of.” Why? Those aren’t observable behaviors and won’t get you any closer to correct and effective performance.

I always try to involve members of the learning audience as early as possible in a project—preferably in the design process. It’s tempting to wait until I feel that my analysis is complete before sketching possible solutions. I sometimes want to wait until my solution is more polished to test it with end users. However, design is a form of analysis.

By getting feedback from learners early, even if my ideas for interactions are only captured with whiteboard sketches, I can find out early on whether I’m headed in the right direction. This helps me quickly find out where the real barriers to performance are and minimizes the risk of major design changes later on in the project.

Ultimately, helping learners confidently and consistently do the right thing at the right time is our goal as designers. To do this, we not only must be experts in learning design, but also well versed in the variables and challenges that influence the behaviors we teach. These are daunting and rewarding challenges. Luckily there is no shortage of tools, processes and strategies to help you get there.

Use the comments section below to tell us about the techniques which have worked for you.

Comic from: http://thenewid.com/2015/04/15/the-multi-talented-instructional-designer.html

About the Author: Christopher Allen

Strategic Consulting | Performance Design | Product Management | Instructional Design | Agile Certified Practitioner. More than a decade of experience leading the development of cutting-edge digital products and services. Passionate about creating shared vision among teams of stakeholders, sales professionals, engineering talent, quality assurance, and support. Prior to Allen Interactions, successful experience in sales management and as a magazine publisher. Master’s Degree in Organizational Management from The George Washington University, Successive Approximation Model (SAM) expert, Agile Certified Practitioner (PMI-ACP) and an avid triathlete.

Comments

Would you like to leave a comment?

Related Blog Posts

By: Christopher Allen | Aug, 2017

Category: Custom Learning, Strategic Consulting

Blog

mLearning Guidelines to Custom Interfacing and Touch-Based Interactions

By Christopher Allen, MA, PMI-ACP, Product Manager “There’s no better learning technique than preparing to teach others.” Valid? Yes. Implications? ...

By: Christopher Allen | Jun, 2015

Category: Custom Learning

Blog

3 Ways to Put the Serious eLearning Manifesto iPad App to Work

By Christopher Allen, MA, PMI-ACP, Product Manager “There’s no better learning technique than preparing to teach others.” Valid? Yes. Implications? ...

By: Christopher Allen | Nov, 2014

Category: Custom Learning, Digital Engineering, Strategic Consulting